Wiring a commercial garage door opener isn’t something you want to wing, it can lead to electrical hazards, code violations, or a door that just doesn’t work right. Whether you’re handling the install yourself or overseeing a contractor, knowing the basics helps you spot problems before they become expensive headaches. This is one area where professional garage door services really prove their worth, but understanding the fundamentals keeps you informed either way. The right approach involves the right tools, solid electrical knowledge, and strict adherence to safety protocols.

Proper Tools and Equipment

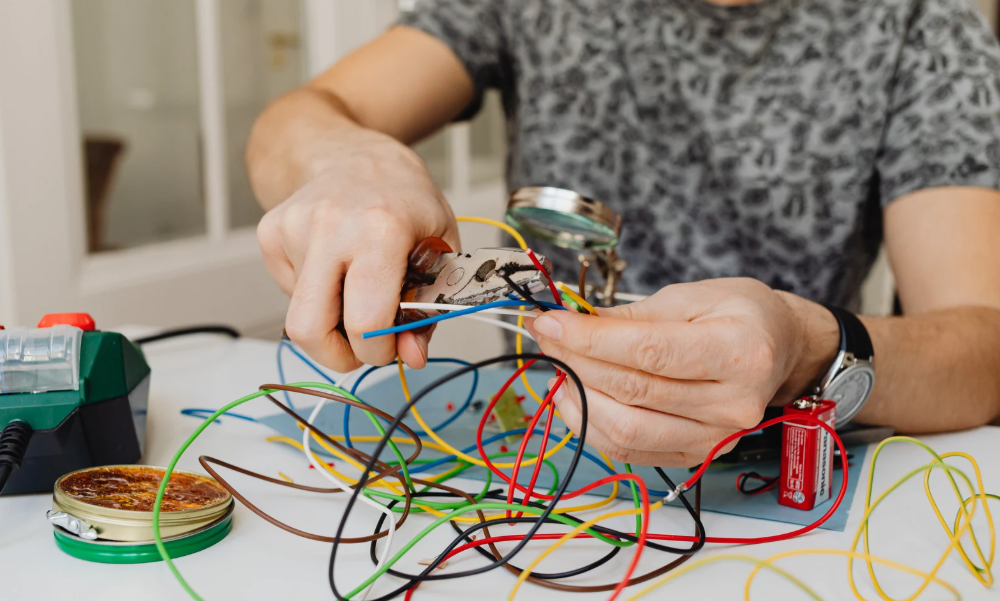

Before touching a single wire, make sure your toolkit is actually up to the task. A voltage tester is non-negotiable, you need to confirm power is completely off before you start messing with anything. Wire strippers should give you clean, precise cuts without nicking the copper beneath, and wire nuts should create connections that won’t come loose over time. Grab a screwdriver set with insulated handles, because regular ones aren’t worth the risk when electricity is involved.

You’ll also need a drill with appropriate bits for mounting, a sturdy ladder, and safety glasses because debris has a way of finding your eyes. Keep a multimeter handy for testing circuits. Cheap tools make the job harder, invest in quality equipment, and the installation goes smoother.

Understanding Electrical Basics

A solid grasp of electrical fundamentals separates a safe installation from a dangerous one.

Voltage compatibility matters more than most people realize. The opener has specific voltage requirements, and your electrical system needs to match. Running an incompatible voltage damages the motor and creates fire risks.

Circuit knowledge matters just as much. Understanding how series and parallel configurations work helps you connect everything correctly without overloading the system or creating short circuits. If circuits seem confusing, that’s a sign to bring in someone who handles this regularly.

Wire sizing might seem like a minor detail, but it’s actually critical. Undersized wires overheat under load, and overheated wires start fires. Match the wire gauge to the current requirements listed in the opener’s specifications, this isn’t a place to guess or substitute what you have on hand.

Safety Precautions and Gear

Electrical work demands respect, and commercial garage door openers are no exception. Before starting any wiring, put on insulated gloves and safety glasses. Use your voltage tester to confirm power is actually off; don’t just flip the breaker and assume it’s off. Circuits get mislabeled, and assumptions get people hurt.

Proper grounding prevents electrical hazards that might not show up until something goes wrong. Follow all manufacturer instructions and local building codes without shortcuts. Code requirements exist because inspectors have seen what happens when people skip steps.

Installing a commercial garage door opener requires attention to detail and consistent adherence to safety protocols. The right gear and precautions significantly reduce accident risks and result in an installation that passes inspection the first time.

Identifying Wires and Connections

Commercial garage door opener installations involve multiple wires serving different functions, and mixing them up causes problems ranging from non-functional doors to electrical fires.

Start by familiarizing yourself with standard color codes from the installation manual. Colors indicate specific functions, and manufacturers follow these conventions for good reason. As you work, label each wire with markers or tape, this saves headaches during troubleshooting down the road.

Before powering anything up, compare your wiring connections against the manufacturer’s diagram. Errors at this stage cause malfunctions or safety hazards that are much harder to diagnose once everything is buttoned up.

Following Manufacturer’s Guidelines

The manufacturer’s guidelines exist because engineers tested these units extensively. These documents outline specific wiring instructions, safety requirements, and operational parameters that need to be followed precisely.

Deviating from manufacturer recommendations doesn’t just void warranties; it compromises functionality and creates genuine safety risks. The guidelines reflect industry standards and lessons learned from installations that went wrong.

By following the provided instructions carefully, you confirm that the installation is done correctly, and the opener will function efficiently for years.

Testing and Inspection Processes

After completing the wiring, thorough testing confirms everything works as intended. Use a multimeter to check voltage levels and verify they fall within the recommended range, voltages outside spec damage motors and shorten equipment life.

Inspect all moving parts for wear, and lubricate components where the manual specifies. Smooth operation extends the lifespan of mechanical parts and reduces strain on the electrical system.

Safety features require verification before calling the job complete. Test the auto-reverse mechanism by placing an obstruction in the door’s path, it should reverse immediately. Check that photo-eye sensors detect objects and stop the door appropriately. These features prevent injuries, and they’re required by code.

Related Topics:

Leave a Reply